Reducing Viral Pathogens By 99.92%

We have engineered a clear plan to create a safer and cleaner environment. We have a Performance Solution highlighting air cleaning technology, potential threats to under-maintained equipment, and solutions that will more comprehensively manage your risk and protect your environment.

Air Purification Methods

Bi-Polar Ionization

Bi-Polar Ionization tubes clean the air you breathe, without using chemicals or creating unwanted byproducts.

Ion tubes engineered and placed in line with the system's airflow will overload the air with both negative and positive charged ions.

These ions once in the airflow will attack and destroy all airborne and surface viruses, bacteria, VOC's and germs.

Once attached, these viruses are no longer harmful.

Bi-Polar Ionization is the only technology that can continually clean the air within a space.

Our engineered Ionizer integrates with the existing HVAC system.

Bi-Polar Ionization does not wait for the pollutants to find their way into the filter inside the air handler. Instead, air ions go to the contaminants in the space where you breathe.

With the Bi-Polar Ionization product, we can monitor in real-time particulate matter, Volatile organic compounds, and relative humidity in the space with the addition of a monitoring system.

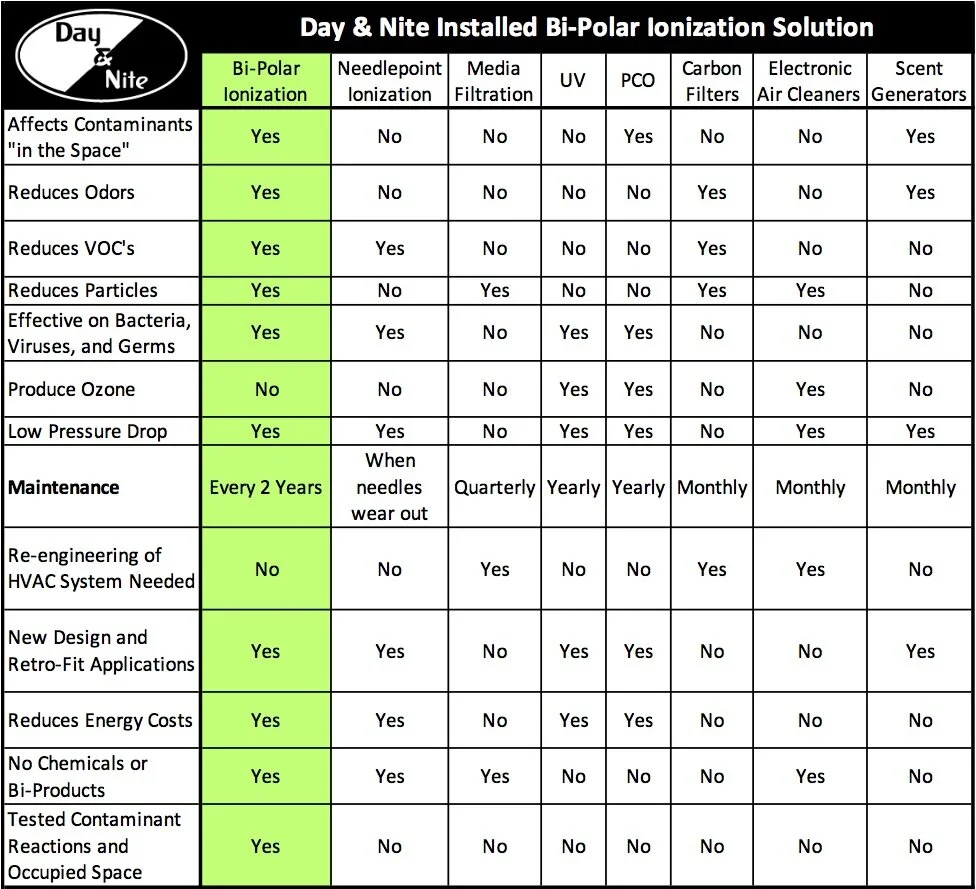

How does our Bi-Polar Ionization Solution compare to others?

See the effectiveness in the Microchem Case Study

Inactivation Mechanism

After 30 minutes, 99.92% more of the virus was inactivated.

Many disinfectant cleaners are momentary, ours is continuous.

Test was commissioned to have same ion concentration range that we aim to achieve in the real world per our system specifications.

Positive ions (H*) and negative ions (O2-) cluster around the spike protein (a surface protein that attaches to an organist and triggers the infection) of the airborne virus, and are converted to hydroxyl radicals (*OH), a powerfully active substance. By stealing H (hydrogen) from within the spike protein, the ions react and combine chemically to form water (h2O). Because the spike protein is damaged, the virus cannot infect cells even when introduced into the body.

Photohydroionization Advance Oxidation

Reduce

Photohydroionization Advance Oxidation is the most effective way to reduce airborne micro-organisms that pass through light rays. It is incredibly effective at reducing gases, vapors, or odors, unlike Germicidal UV light, which only reduces the airborne micro-organisms.

Purify

A PHI Cell provides safe hydrogen peroxides to purify the air. Hydrated quad-metallic compound targets develop the advanced oxidation reaction that creates a triple function without any maintenance to the unit.

Freshen

Reduce micro-organisms by over 95% and significantly reduce gases, VOCs, and odors, leaving the space fresh and clean, completely odor-free.

Eliminate

Helps eliminate sick building syndrome.

Air Quality Maintenance

Evaporator Coil Cleaning

Facts

Dirty evaporator creates a direct threat to the air quality in the space.

Evaporator coils are a breeding ground for mold, bacteria build-up, dirt, and pathogens.

All existing airborne particles, viruses, and bacteria return through the coil and will continue to grow.

Evaporator drain pans are standing water that breeds airborne bacteria directly into the air stream.

Solutions

Chemically Clean and sanitize evaporator coils with proper chemicals.

Blackhawk aerosol

Evap Power C

Wash coil for removal of all chemical Sanitize and clean Evaporator drain pan to remove all existing build-up.

Protect and coat coil with Cal Shield to reduce the ability for dirt, and bacteria to adhere to coil.

Install Pan pads to Condensate pans to control the growth of harmful bacteria.

Ice Machines

Facts

Commercial Ice machines are prone to microbial contamination if not cleaned well regularly.

People reaching in to remove ice with dirty hands and or using Dirty scoopers to remove ice are one of the visible issues.

The non-visible biofilm, slime, bacteria, and pathogens are another issue.

Regular maintenance and cleanings must be performed to prevent bacteria and additional health factors to arise.

Solutions

Provide a full sanitization of the head and bins using a food safe cleaner.

Ice Machine Treatment System installed.

Use of a Treatment & Odor Determent System will keep the machine cleaner for a longer period, cutting down on how often a professional cleaning is needed.

A high-intensity UV light targeted on a hydrated Quad-Metallic target creates safe, low-level Hydroperoxides, Super-oxide Ions, Hydroxyl Radicals, and Hydroxides. These are all aggressive but friendly gaseous oxidizers. These oxidizers revert to oxygen and hydrogen, leaving no chemical residue or dangerous compounds.

Walk In Box and Food Prep Room

UV Light Rays

Eliminates airborne Viral Pathogen, bacteria, mold, odors, and VOC's

Airborne microbes are destroyed as air passes through the high-intensity UV light rays. The atmosphere of hydroxyl redials, hydro-peroxides, and superoxide ions oxidize the air with friendly oxidizers. These oxidizers revert back to oxygen and hydrogen, leaving no chemical residue or dangerous compounds.